|

||||

| INDEX | next

|

|

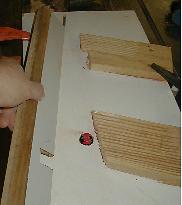

Only a small hole is

needed in the router table to get the router bit through without interference.

The same goes for the slot in the fence. Large holes increase the chances

of the strip getting caught in the gap and cause other problems. |

|

A single 3" screw holds the router fence in place acting as a pivot. |

|

The life and accuracy of the fence is increased with a strip of formica epoxied to the poplar. Any hard, smooth and abrasion resistant material is fine. This becomes more of an issue when you mill many thousands of feet and more. |

| INDEX |

| Home | Kayak Designs | Kayak Shop | Materials | Kayak Gallery | About us |

| Building Manual | Plans | Sandwich Core | Wood Kayak | Order | |

| Epoxy Test | Abrasion Cloth | Rudder | Resources | Choosing Kayak | Guestbook |

If you notice any problems with the site (i.e. error links, missing images) please, let me know. Thanks

Mail:

Vaclav Stejskal

58 Wood Ln.

Acton, MA 01720

USA

Tel: 781-481-9261

© 1999

- 2024 Copyright Vaclav Stejskal

All rights reserved

Last page update:

9 May 2024